Beschreibung

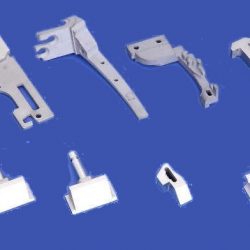

Premium Building Hardware Items – Investment Casting Specialists

Hochwertige Gussbauteile – kundenspezifische Metallkomponenten

As a leading investment casting manufacturer in China, we specialize in high-quality metal components for various industries. Our commitment to excellence ensures superior products, competitive pricing, and exceptional service for global clients.

0,1 kg bis 3000 kg (größere Teile durch Sandguss erhältlich).

- ISO 9001:2008 certified and SGS audited manufacturing facility

- 20+ years of experience in precision casting solutions

- Comprehensive quality control from raw materials to finished products

- Competitive pricing with direct factory benefits

- Custom OEM/ODM services for unique requirements

Kommunale Infrastruktur

We utilize advanced investment casting (lost wax casting) techniques alongside other manufacturing processes including:

- Sand casting

- Gravity casting

- Die casting (aluminum/zinc alloys)

- Precision machining

Material Selection

Wide range of materials available:

- Aluminum alloys: A380, A383, ADC10, ADC12, ALSi9Cu3

- Zinc alloys: Zamak 3, Zamak 5

- Stainless steel, carbon steel, brass/copper

- Grey iron and ductile iron

Product Applications

Our investment casting solutions serve multiple industries:

- Construction hardware (doors, windows, cabinets)

- Automotive and motorcycle components

- Machinery parts and tooling components

- Plumbing and bathroom fixtures

- Badezimmerarmaturen

Complete Production Process

- Precision casting using investment/lost wax method

- Secondary machining: CNC turning, milling, drilling

- Quality inspection at every stage

- Surface finishing options: plating, painting, powder coating

- Careful packaging according to client specifications

Our Advantages

- Fast response – quotes within 24 hours

- Engineering support for design optimization

- Strict confidentiality for all client projects

- Flexible payment terms

- Efficient logistics with global shipping

How to Order

Simply send your 2D/3D drawings or samples for evaluation. Our engineering team will provide:

- Detailed quotation

- Material recommendations

- Production timeline

- Shipping options

Typical lead time: 30-35 days for samples after tooling confirmation, plus 30-35 days for production after sample approval.

Related Product Categories:

hardware component | cabinet hardware | door hardware | investment casting parts | precision metal components