We provide investment casting also called as “precision casting”,“lost wax casting” or “ wax loss casting”. The process we use is silica sol investment casting which is an advanced metal-forming process. First wax pattern would be made from aluminium (or steel) mold according to the item shape,then a ceramic shell would be built surrounding the wax pattern. After dewax, the ceramic shell becomes a new mold in which molten steel would be poured, so that high dimensionally accurate & intricate parts could be produced.

Materials Used In Our Production:

We handle different kinds of steel materials for lost wax precision investment castings, such as stainless steel, carbon steel, alloy steel, tool steels, precipitation hardening steels etc. All the materials are conforming to various international standards

Weight Range:From few grams to 30 Kgs.

Size Range:500mm x 500mm x 500mm.

Reports offered:Material chemical composition report,Dimension measuring report,Hardness testing report.

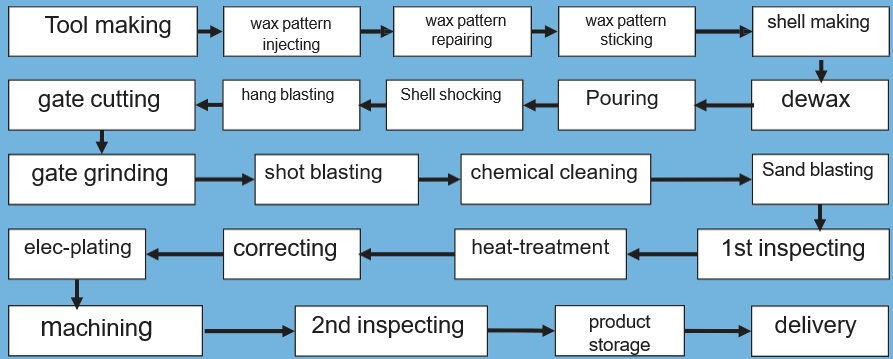

Work Flow

Advantage Of This Process:

1.Very low tool cost makes it possible for small order and personalized customization

2.Complex shape & size can be easily casted,helps optimizing the solution for complex design,saving time and money.

3.Excellent surface finish and high dimensional accuracy give products a near net shape wherein machining is either totally eliminated or reduced to a minimum.

4.Accurate reproduction of fine details e.g.beautiful textures,characters,letters and slots,holes is achieved.

5.Possible to produce a very wide variety of products across different industries.