Carbon

steel casting parts from China are extensively used in Europe across

industries such as construction, machinery, automotive, and energy.

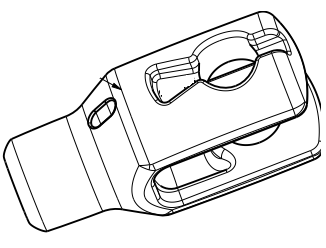

Chinese foundries produce durable and cost-effective components like

gears, brackets, housings, and structural parts using advanced casting

techniques, including sand casting and investment casting. Carbon

steel’s strength, versatility, and affordability make it ideal for

heavy-duty applications.

Chinese manufacturers adhere to

international standards like ISO 9001 and ASTM, ensuring high-quality

production. European industries benefit from China’s competitive pricing

and large-scale manufacturing capabilities while maintaining compliance

with EU regulations, such as CE marking and PED (Pressure Equipment

Directive) for specific applications. This collaboration enables

European companies to access reliable, precision-engineered carbon steel

castings that enhance operational efficiency and reduce costs. By

leveraging China’s expertise, Europe strengthens its supply chain and

supports innovation in manufacturing and infrastructure projects,

ensuring robust solutions for demanding industrial needs.